The reference design used sensorless field-oriented control without a position sensor, aiming to reduce development time and enhance system efficiency.

For decades, the internal combustion engine (ICE) has powered not only cars but also their heating and cooling systems. As the automotive industry moves towards electrification, transitioning to hybrid electric vehicles (HEVs) with smaller combustion engines or fully electric vehicles (EVs) without engines, the heating, ventilation, and air-conditioning (HVAC) systems are increasingly driven by a PMSM motor that powers the eCompressor using high-voltage electricity. This eCompressor is crucial for cooling, heating via a heat pump, and managing the thermal conditions of other powertrain systems like the battery pack and traction drive. Today, the eCompressor in HEVs and EVs faces a growing set of requirements, including lower costs, smaller size, reduced vibration and noise, as well as higher power levels and increased energy efficiency. The TIDM-02012, a high-voltage HEV/EV HVAC eCompressor motor control reference design from Texas Instruments (TI), demonstrates controlling an eCompressor motor using field-oriented control (FOC) without requiring a position sensor.

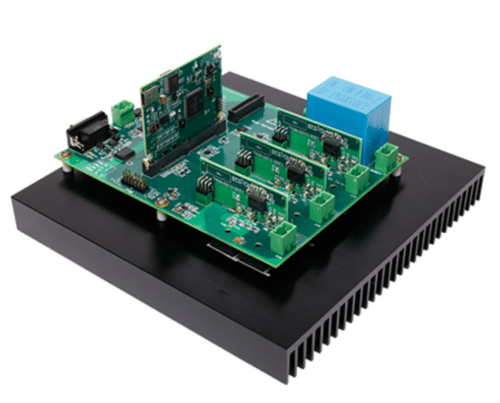

The system is designed to reduce the number of critical components in the bill of materials, enhance efficiency, and minimize vibration and noise, while also saving development time. It is based on the TMS320F28003x real-time controller series and offers scalability with future MCUs in the portfolio using the controlCARD-based form factor. Additionally, the design accommodates both multi-shunt and single-shunt current sensing modes to cater to various design objectives. An isolated gate driver is included to support 400V and 800V DC bus voltages, aligning with the industry’s shift towards higher voltage levels.

In the automotive sector, applications such as HVAC compressors and Positive Temperature Coefficient (PTC) heaters both utilize high voltage and require isolated communication. These components are crucial for ensuring effective climate control and heating within vehicles, operating under stringent safety and efficiency standards to handle the high voltage demands safely.

The features of this reference design include sensorless Field-Oriented Control (FOC) utilizing the InstaSPIN FAST observer, which operates on a cost-optimized C2000 real-time microcontroller. The hardware and software provided with this design have been thoroughly tested and are ready-to-use, significantly accelerating development time to market. This design supports a variety of software capabilities such as field-weakening control, Maximum Torque Per Ampere (MTPA), over modulation, and vibration compensation through incremental software builds that allow verification of different software modules step by step. It also offers operation across a wide speed range, starting from 5 electric Hz, and includes support for CAN FD and LIN interfaces, along with motor over-current protection using on-chip comparators.

TI has tested this reference design. It comes with a Bill of Material (BOM), schematics, assembly drawing, Printed Circuit Board (PCB) layout, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.

The post HEV/EV HVAC eCompressor Motor Control Reference Design appeared first on Electronics For You.

View more at https://www.electronicsforu.com/electronics-projects/hev-ev-hvac-ecompressor-motor-control-reference-design.

Credit- EFY. Distributed by Department of EEE, ADBU: https://tinyurl.com/eee-adbu

Curated by Jesif Ahmed