Advanced convection architecture and smart power control aim to raise profiling precision while cutting operating costs in high-mix SMT lines. A new 16-zone reflow oven configuration by Kurtz Ersa is positioning itself as a high-performance option for electronics manufacturers seeking tighter thermal control and improved process efficiency in surface-mount production. The HOTFLOW THREE platform integrates […]

Advanced convection architecture and smart power control aim to raise profiling precision while cutting operating costs in high-mix SMT lines. A new 16-zone reflow oven configuration by Kurtz Ersa is positioning itself as a high-performance option for electronics manufacturers seeking tighter thermal control and improved process efficiency in surface-mount production. The HOTFLOW THREE platform integrates […]View more at https://www.electronicsforu.com/news/16-zone-reflow-platform-targets-higher-thermal-stability.

Credit- EFY. Distributed by Department of EEE, ADBU: https://tinyurl.com/eee-adbu

Curated by Jesif Ahmed

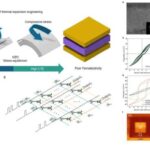

Thermal constraining technique stabilizes ferroelectric transistors, boosting efficiency and endurance for next-gen electronics. A team led by Professor Taesung Kim at Sungkyunkwan University has unveiled a semiconductor design technique that uses thermal forces to dramatically improve next-generation AI chip performance while trimming energy use a development that could help solve one of electronics’ toughest challenges: […]

Thermal constraining technique stabilizes ferroelectric transistors, boosting efficiency and endurance for next-gen electronics. A team led by Professor Taesung Kim at Sungkyunkwan University has unveiled a semiconductor design technique that uses thermal forces to dramatically improve next-generation AI chip performance while trimming energy use a development that could help solve one of electronics’ toughest challenges: […] New MIT process embeds matching hardware fingerprints in paired chips for direct, server-free authentication. Researchers at the Massachusetts Institute of Technology have unveiled a novel chip-fabrication technique that could reshape hardware-level security for electronic systems by enabling paired microchips to authenticate one another directly using shared physical identifiers. At the core of the approach is […]

New MIT process embeds matching hardware fingerprints in paired chips for direct, server-free authentication. Researchers at the Massachusetts Institute of Technology have unveiled a novel chip-fabrication technique that could reshape hardware-level security for electronic systems by enabling paired microchips to authenticate one another directly using shared physical identifiers. At the core of the approach is […] MIT’s new fabrication trick gives paired chips matching physical IDs for secure, server-less authentication. In hardware security news, researchers at the Massachusetts Institute of Technology have developed a new chip-processing method that could tighten cryptographic security at the device level by creating paired physical fingerprints on microchips. This technique addresses a longstanding challenge in secure […]

MIT’s new fabrication trick gives paired chips matching physical IDs for secure, server-less authentication. In hardware security news, researchers at the Massachusetts Institute of Technology have developed a new chip-processing method that could tighten cryptographic security at the device level by creating paired physical fingerprints on microchips. This technique addresses a longstanding challenge in secure […] APPLY HERE Location: Bengaluru Company: Tesla Position Description The Tesla AI Hardware team is at the forefront of revolutionising artificial intelligence through cutting-edge hardware innovation. Comprising brilliant engineers and visionaries, the team designs and develops advanced AI chips tailored to accelerate Tesla’s machine learning capabilities. Their work powers the neural networks behind Full Self-Driving (FSD), and Tesla humanoid robot, […]

APPLY HERE Location: Bengaluru Company: Tesla Position Description The Tesla AI Hardware team is at the forefront of revolutionising artificial intelligence through cutting-edge hardware innovation. Comprising brilliant engineers and visionaries, the team designs and develops advanced AI chips tailored to accelerate Tesla’s machine learning capabilities. Their work powers the neural networks behind Full Self-Driving (FSD), and Tesla humanoid robot, […] What if robots could be trained in full digital factories before touching the real world? Can a simulation model make that possible? AuraML has introduced AuraSim, a multimodal world simulation model built to generate physics-ready environments for robotics. The platform converts inputs such as text, floorplans, videos, depth maps, and point clouds into simulation-ready digital […]

What if robots could be trained in full digital factories before touching the real world? Can a simulation model make that possible? AuraML has introduced AuraSim, a multimodal world simulation model built to generate physics-ready environments for robotics. The platform converts inputs such as text, floorplans, videos, depth maps, and point clouds into simulation-ready digital […] New nanoscale research reveals how molecular stiffness could cap the performance of flexible wearable tech. Researchers at University of Cambridge have taken a first experimental step toward understanding how the molecular mechanics of flexible semiconductors might constrain the performance of future wearable electronics suggesting there could be inherent limits to how fast and efficient bendable […]

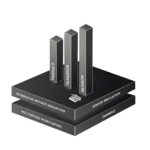

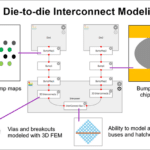

New nanoscale research reveals how molecular stiffness could cap the performance of flexible wearable tech. Researchers at University of Cambridge have taken a first experimental step toward understanding how the molecular mechanics of flexible semiconductors might constrain the performance of future wearable electronics suggesting there could be inherent limits to how fast and efficient bendable […] The tool aims to ease the challenges of designing intricate 3D interconnects, offering engineers a way to handle multi-die systems more efficiently in AI data centre applications. Keysight Technologies has introduced 3D Interconnect Designer, part of its EDA portfolio, to support the growing intricacy of chiplet and 3DIC packages. The software aims to streamline workflows […]

The tool aims to ease the challenges of designing intricate 3D interconnects, offering engineers a way to handle multi-die systems more efficiently in AI data centre applications. Keysight Technologies has introduced 3D Interconnect Designer, part of its EDA portfolio, to support the growing intricacy of chiplet and 3DIC packages. The software aims to streamline workflows […] The new MIT platform uses multiple materials to fabricate complex electric motors in hours a potential game‑changer for on‑site electronics production. In a major advance for additive manufacturing and electronics fabrication, researchers at the Massachusetts Institute of Technology have demonstrated a 3D‑printing system capable of producing fully functional complex electric machines including a complete linear […]

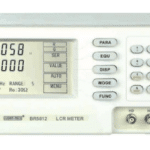

The new MIT platform uses multiple materials to fabricate complex electric motors in hours a potential game‑changer for on‑site electronics production. In a major advance for additive manufacturing and electronics fabrication, researchers at the Massachusetts Institute of Technology have demonstrated a 3D‑printing system capable of producing fully functional complex electric machines including a complete linear […] What if one bench top instrument could handle wide frequencies, multiple parameters, fast measurements, and production sorting in a single setup? Find out! The BR 5812 from KUSAM-MECO is a versatile LCR meter built for engineers, technicians, and researchers who need fast, accurate, and reliable measurement of electronic components. It solves common problems like slow […]

What if one bench top instrument could handle wide frequencies, multiple parameters, fast measurements, and production sorting in a single setup? Find out! The BR 5812 from KUSAM-MECO is a versatile LCR meter built for engineers, technicians, and researchers who need fast, accurate, and reliable measurement of electronic components. It solves common problems like slow […]