Protective Actions to Reduce & Avoid Electric Hazardous

General Rules

As general safety rules for EHV, HV and MV installations (EHV: Extra High Voltage – V ≥ 150 kV. HV: High Voltage – 60 kV ≤ V < 150 kV. MV: Medium Voltage – 1 kV < V < 60 kV), those related physical with the protection of the site, taking into account the access to the equipments and the basic principles of operation and maintenance of the equipments, are fundamental.

All applicable laws, internal and official regulations and national and/or international standards must be accomplished, in what concerns equipments and health and safety.

Indoors equipments must be installed in rooms with doors and lock, in order that only authorized people can reach them.

There are some actions that must be carried out in order to avoid the hazardous of electricity.

As general rules it must be considered:

- Electrical installations must be easy to understand and properly maintained

- Use of equipments with reduce voltage (≤ 25 V – humid or wet places – or ≤ 50V), whenever possible

- Use of equipments with reinforced insulation

- Adequate degrees of protection provided by enclosures (IP and IK codes)

- Earthing of all metallic structures

- All live metallic parts not enclosed must be segregated by means of fences or similar

- Around switchboards it must exists enough space available for the circulation of personnel

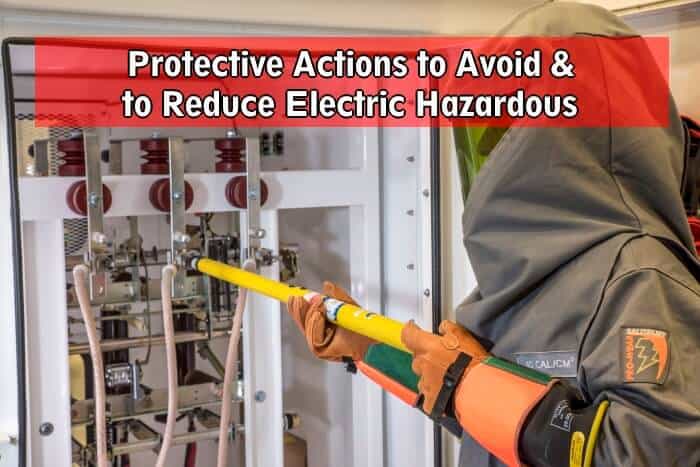

- Only specialized personnel, using appropriated tools must perform any work on electrical installations

- In case of fire power supply must be immediately interrupted and the personnel must:

- Give the alarm immediately

- Use appropriated protection masks against toxic gases

- Proceed to smoke exhaustion

- Close all doors, windows and other openings, to avoid the spread of fire

- Fight the fire using extinguishing portable equipment (ABC powder or CO2)

Related Article: All About Electrical Protection Systems, Devices And Units

To perform work on electrical installations the employees must follow very severe rules that must be in accordance with the laws and the regulations, and also with the internal procedures produced by the company.

The part of the installation subject of intervention must be de-energized and connected to the earth.

Employees must be equipped with protective clothing, helmet, glasses dielectric footwear and insulation gloves. An insulation mat shall be placed at the local of the intervention.

The working area must be delimited using barriers, tapes, fences or other similar equipments, in order to avoid the entrance of non authorized people.

After the conclusion of work, and before energizing, it must be assured that the work was done properly and that all personnel is aware that power is going to be connected.

Only the responsible of the employees in charge of work is allowed to reconnect power.

Safety Interlocks

In order to avoid wrong manoeuvers that can damage the equipment and cause hazards to the employees an interlocking programme must be implemented.

Most common wrong manoeuvers are:

- Open or close isolators with the circuit breakers closed (on load manoeuvre).

- Close earthing switches with circuit breakers and/or isolators closed and with voltage present.

- Close circuit breakers and/or isolators with earthing switches closed.

- Close other circuit breakers when the protection relay 50BF, “circuit breaker failure”, is activated.

Also Read: Transformers Fire Protection System – Causes, Types & Requirements

There are two types of interlocking: electrical and mechanical.

Electrical interlocking is intended to prevent non authorized electrical control and is performed through “hardware” (relays and cabling) and/or through “software”.

Mechanical interlocking is intended to prevent local manual control and can be achieved by padlocks and locks, or can be built-on, which is the case of isolators with earthing switches.

Equipments can be provided with both electrical and mechanical interlocking.

Equipments with Accessible Live Parts

All electrical equipments with accessible live parts, such as auxiliary transformers and capacitor banks, must be protected by a fence with a door locked with a padlock as shown on the figure below, in order to avoid the entrance of personnel with the equipment energized.

The fence must be connected to the earth grid and the door must be provided with a micro-switch to trip the protective device if by any chance any person tries to enter the area.

In case of capacitor banks the opening of the door must have a time delay interlocking to assure that the capacitor bank is completely discharged.

Electrical Safety Signs

At EHV, HV and MV installations electrical safety signs must be placed, stating the existence of electrical installations and that there is danger of electrocution.

These signs must be written in the language of the country where they are installed and they must comply with the applicable technical standards.

Electrical safety signs must be placed, at least, at all fences, doors of compartments with electrical equipment, metallic towers and structures, switchboards and batteries.

The post Protective Actions to Avoid & to Reduce Electric Hazardous appeared first on Electrical Technology.

July 29, 2018 at 09:57PM by Department of EEE, ADBU: https://ift.tt/2AyIRVT