Discover the benefits of this approach, which enhances vehicle ambience and communication and tackles manufacturing challenges and ensures a blend of aesthetic appeal, functionality, and long-term reliability in automotive design.

The evolving automotive industry continuously seeks innovative ways to enhance vehicle aesthetics and functionality, which is reflected in the sophisticated use of RGB LED lighting within car interiors. These LEDs are pivotal in elevating the ambience, brand differentiation, and interactive communication with the driver. For example, changing dashboard lights can indicate the activation of autonomous driving modes or alert the driver to specific attention needs. This dynamic application necessitates the integration of numerous RGB LEDs throughout the vehicle’s dashboard and cabin areas.

This integration presents significant design and manufacturing challenges. Traditionally, LEDs’ color accuracy varies, requiring either a meticulous sorting process to ensure uniformity or on-the-line calibration—both of which are time-consuming and costly. Furthermore, LEDs are prone to performance degradation due to temperature variations and aging, complicating long-term maintenance and functionality.

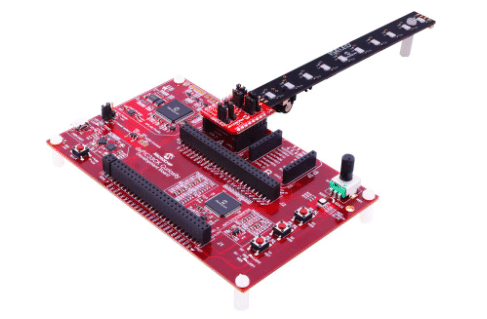

Implementing the ISELED (Intelligent Smart Embedded LED) technology represents a transformative shift in addressing these issues. ISELEDs are pre-calibrated at the vendor level, dramatically simplifying manufacturing processes by eliminating the need for in-line calibration and reducing variability among LEDs. The dsPIC33CK Digital Signal Controller (DSC) family from Microchip Technology further enhances the ISELED implementation. These controllers are designed to optimize system costs and simplify circuit design. Key features include 3V operation compatible with 5V inputs, eliminating the need for additional components like glue logic or level shifters.

Optimizing Performance and Safety

The dsPIC33CK DSCs are also highly cost-effective, offering various models with scalable memory options ranging from 32KB to 1024KB, and they include robust communication capabilities such as CAN-FD and LIN, essential for automotive applications. These DSCs support a low overhead ISELED implementation by utilizing on-chip Core Independent Peripherals (CIPs), which reduce CPU load by handling specific tasks independently. A specialized 5-bit hardware SPI mode and flexible hardware CRC are instrumental in streamlining the frame creation process for ISELED, further offloading CPU tasks. Moreover, the increased throughput for ISELED animations and light effects is achieved through Direct Memory Access (DMA), enhancing the overall visual experience without burdening the CPU.

Regarding functional safety, the dsPIC33CK DSC family is designed to meet the rigorous ISO 26262 standards, targeting an ASIL B safety level. This ensures that the lighting system adheres to the highest safety criteria, which is crucial for automotive applications. Robust capacitive touch sensing also adds a layer of interactive capability, enhancing user experience. Combining ISELED technology with dsPIC33CK DSCs offers a cost-effective, optimised solution that addresses the critical challenges of RGB LED applications in automotive environments. This integration simplifies manufacturing and ensures the longevity and reliability of the lighting systems, making it an ideal choice for future-oriented automotive manufacturers.

Microchip has tested this reference design. It comes with a bill of materials (BOM), schematics, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.

The post Reference Design For Automotive Interior Lighting appeared first on Electronics For You.

View more at https://www.electronicsforu.com/electronics-projects/reference-design-for-automotive-interior-lighting.

Credit- EFY. Distributed by Department of EEE, ADBU: https://tinyurl.com/eee-adbu

Curated by Jesif Ahmed